An open platform for supporting production networks' reconfiguration

Our way to resilient manufacturing supply chains

In the rapidly evolving digital landscape, challenges like the COVID-19 pandemic have forced manufacturers to rethink not only their supply chains but also the adaptability of their production facilities. Achieving resilient manufacturing is crucial to maintain high-quality production at efficient rates while reducing non-value-adding activities.

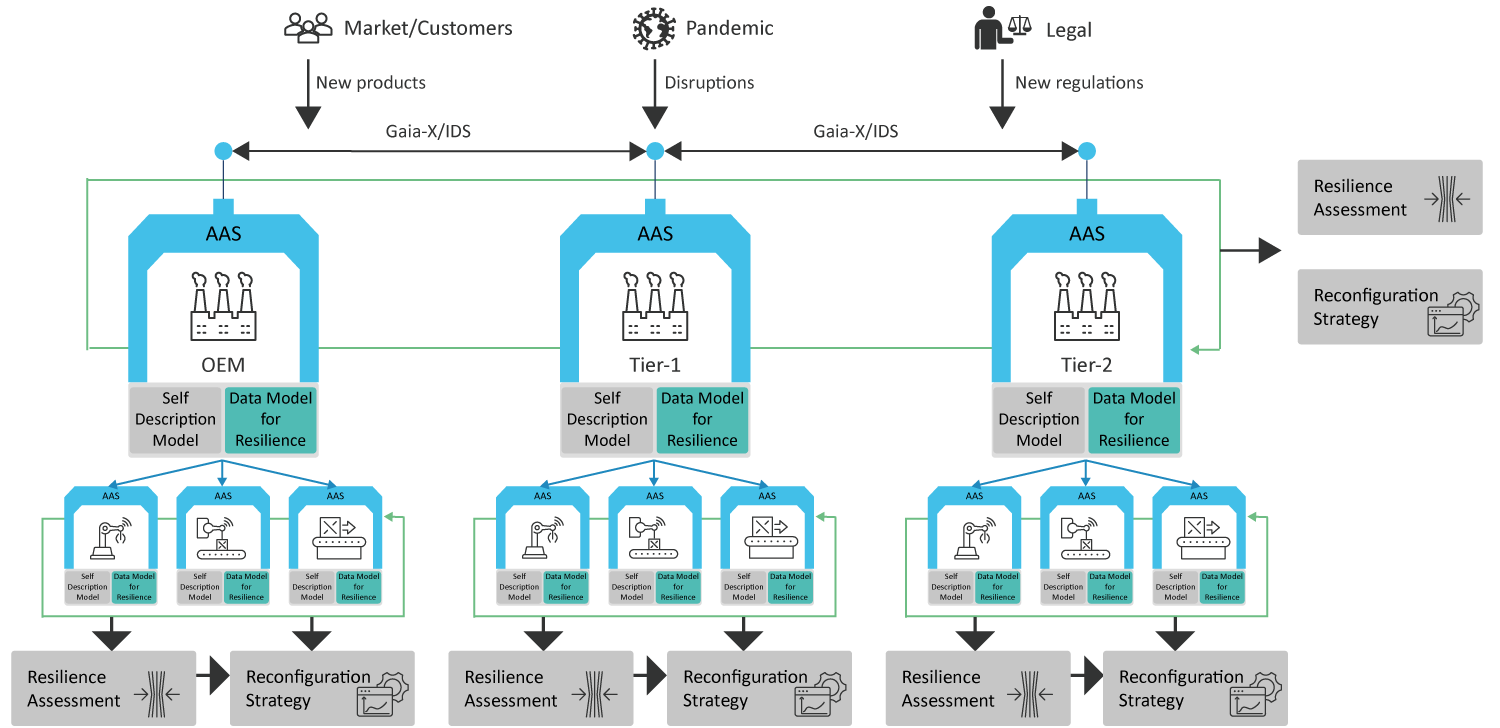

To do this, Flex4Res is utilising advanced platform-based manufacturing techniques. These techniques are anchored in cutting-edge technologies like Gaia-X and International Data Spaces (IDS) which facilitate efficient data sharing across the entire supply chain. Additionally, Flex4Res incorporates the Asset Administration Shell (AAS) for reconfiguring manufacturing processes within the factory. This helps factories to quickly change how they operate to adapt to new requirements or challenges.

Central to Flex4Res is the concept of the Digital Twin, which is a virtual model of the manufacturing network. This technology is crucial for planning and executing reconfiguration processes in highly flexible production systems and networks. The Digital Twin helps in visualising and testing changes before they are implemented in the real-world setup. The key element is the use of Self-Descriptions with linked, standardised information models, which allow a clear and uniform understanding of data across different systems.

The platform and its associated technologies aim to augment current lean management practices in manufacturing, particularly in the context of Industry 4.0. By facilitating better information sharing among stakeholders in the value chain, Flex4Res strives to improve coordination and efficiency, paving the way for more adaptable and therefore resilient manufacturing environments.

The Flex4Res concept

Objectives

Implementation of an open platform based on Gaia-X/IDS reference architecture and asset administration shell

The idea of manufacturing data spaces is still new, and there’s a lot of different tools and ways how to implement them. To make things more uniform, a standard way to share data is needed. Flex4Res is tackling this challenge by setting up an industrial data space where digital twin models of production facilities can be shared. These models are stored in the asset administration shell middleware. The digital twin models help to evaluate how resilient manufacturing processes are (resilience assessment) and to plan any changes that need to be made (reconfiguration planning).

Resilience assessment toolbox for early detection of reconfiguration needs

Resilience means how well a system can handle disruptions and recover quickly. Right now, the industry does not really use a specific way to check how resilient their systems are when they are in the process of decision-making in planning reconfiguration. Flex4Res is going to change that by creating a special toolkit for the resilience assessment. This allows manufacturers to make smarter choices – from a resilience point of view. Moreover, it develops a standard ‘Resilience Data Model.’ This model will be the foundation for building the resilience services.

Decision-making for the application of reconfiguration strategies

Flex4Res will use information from monitoring and prediction tools to help make decisions. With the decision-making tools manufacturers can evaluate alternative reconfiguration strategies. They can analyse ‘what-if’ scenarios and figure out the best ways to adjust, either by making decisions themselves, based on the suggested adaption strategies, or letting the system automatically adapt. To make this work well, we’re going to create a system that’s smart and integrated right into the manufacturing process. This system will be especially useful for complex production systems, like when different steps are combined. It will also help share expert knowledge, making it easier for everyone to understand how to make the best changes.

Test and validate the integrated solution into industrial pilot cases

Flex4Res is going to test and validate the integrated solution into four industrial use cases. These tests will examine adjustments at different levels – from the entire value chain down to individual machines and devices. The use cases also cover different manufacturing volume rates from medium to high rates and different steps, and include various steps in the process. But it is not just about changing production process; it is also about reconfiguring the logistics – how materials and products move around.