Constant reconfiguration of supply plans

Use case with Sidenor Group

Sidenor Group produces a variety of steel products (e.g., merchant bars, plates, wide rods and more). Their processes range from scrap purchasing and metal processing to packaging and delivering to customers. All orders and the corresponding processes are shared among six plants located in the Balkans and Cyprus.

In the project, it is represented by Sidenor Steel Industry S.A. which operates a manufacturing plant in Thessaloniki, Greece.

The challenge

External and internal disruptions require reallocating the production to different production sites than originally planned. Currently, reconfiguration takes place manually and is based on expert knowledge and spreadsheet calculations. Moreover, decisions taken at the network level are not connected to the reconfiguration needed at the factory level.

The vision of the future process

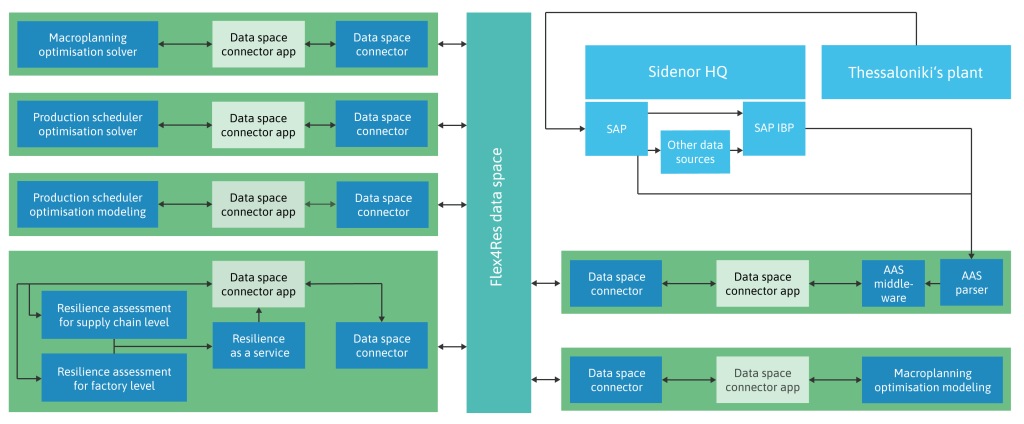

Based on a secure data exchange using IDS and the Asset Administration Shell (AAS) concepts, the resilience toolbox will guide the users through the steps for network reconfiguration by highlighting the differences with the current configuration status. The macroplanning optimisation tool uses data from the Enterprise Resource Planning (ERP) system to reallocate the production among the facilities and update raw material supplies.

In the production scheduler optimisation tool, an Artificial Intelligence (AI) agent will compute the scheduling of Thessaloniki’s plant based on the output of the macroplanning optimisation tool and data from the ERP. The resulting schedule will be displayed to the user through a graphical user interface (GUI).

Involved project partners

- Laboratory for Manufacturing Systems & Automation (Greece)

- Netcompany-Intrasoft (Luxemburg)

- Sidenor Viomichaniki Chalyva Anonymi Etairia (Greece)